Yes, it can be used in any transparent neutral plastic resins.

Yes, but it should be used as a pigment to add road marking paint to replace the position of titanium dioxide

It doesn’t have any chemical reaction with the screws, barrels, or molds, however, the glow pigment is very hard, it will scrub with those metal tools, and possibly make their shelf-life shorter.

Usually add 20-40% of the weight, not more than 50%, depending on the brightness effect you want to achieve.

For small quantities, you can go to Amazon to buy some transparent resin and luminous powder; If the quantity is large, you can consult us through the official website of Glow Technology.

You can add 5%-50% luminous powder by weight to resin, the adding ratio depends on which resin you use and your production process, preferably transparent resin, then the resin can glow in the dark, adding beauty and interest.

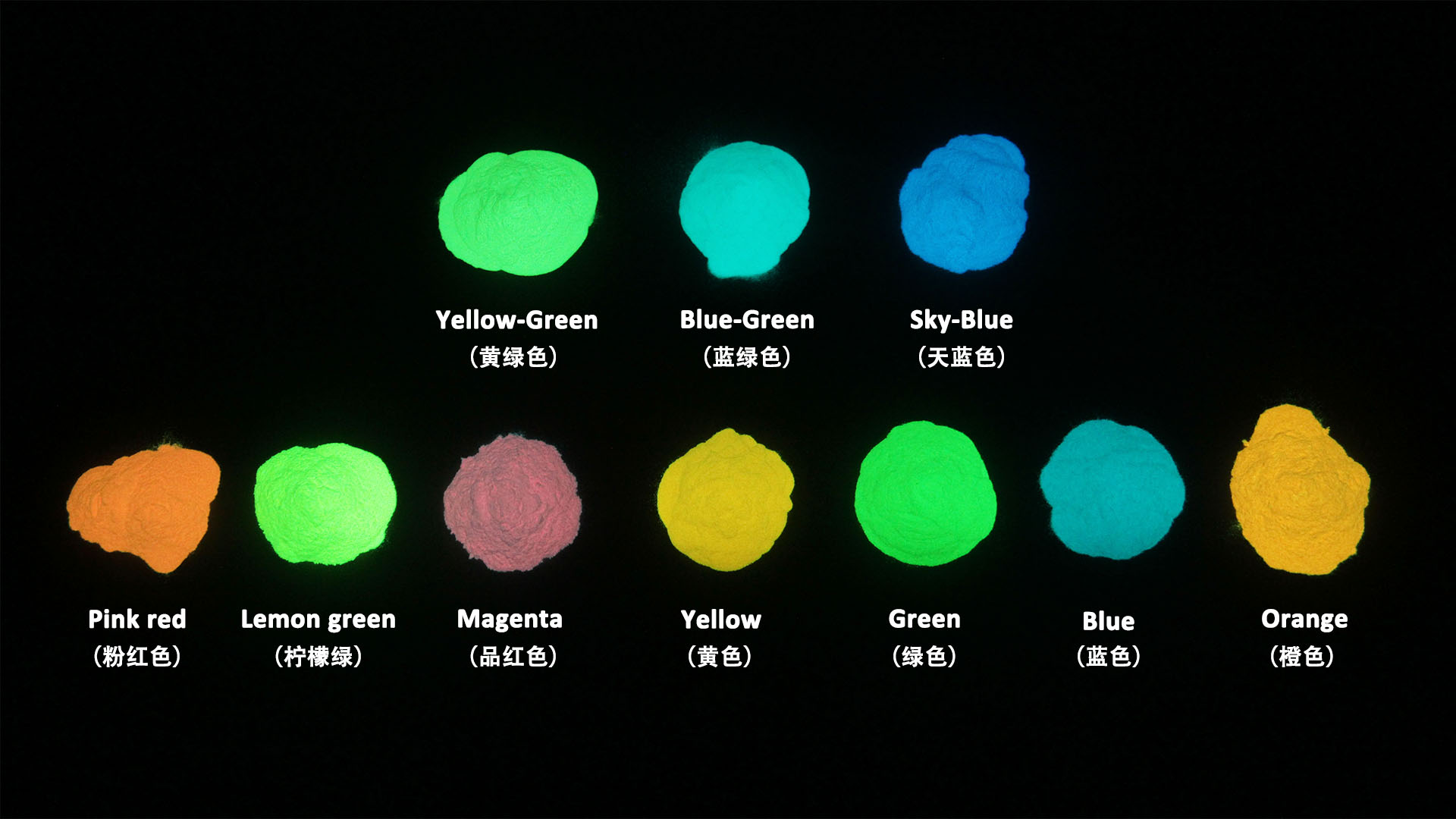

Yellow-green is the brightest, other colors are slightly weaker.

Yes, generally visible light can charge the pigment full of energy within 10-20 minutes and glow in the dark, both indoor or outdoor.

Yes, not necessarily blacklight, generally visible light can make it full of energy and glow in the dark.

Storage: In a dry, cool warehouse, 0℃ – 35℃ (32℉ – 95℉), avoid sunlight, keep it from heat and frozen.

Lifespan: 24 months when sealed properly

After applying, the shelf life depends on the environment, the temperature, the humidity, and also the daily fiction.

These are pigments and do not obtain food contact certificate. Usually, our clients do the test on the glow in the dark masterbatch, not on the pigment. The pigment will be decomposed in strong acid or strong alkaline.

The adding ratio can be a maximum of 50% according to our clients’ experience, depends on how bright you need the material and also your injection molding technology.

These are pigments and do not obtain food approval, usually, our clients do the test on the glow in the dark masterbatch, not on the pigment. The pigment will be decomposed in strong acid or strong alkaline.

Yes, please click to the link.

The best use of temperature is below 500℃. But the test methods are different, I suggest you take samples for testing.

Yes. Glow powder can be used for thermoplastic paint.

Yes. All of Glow technology’s glow powder can last for more than 12hours.

Glow Technology’ glow powder is a strontium aluminate based powder without any polymers.

Yes. Glow Technology’s luminous powder all are long-lasting powder.

The glow effect can last for more than 15 years.

Almost anything you want it to glow, as long as it is a neutral and transparent medium.

As long as the correct adding luminous powder can shine in the dark. The epoxy resin should be as clear as possible to have a better glow effect.

The adding ratio is 5%-20% for the only reference, should not exceed 50%, depends on the glow effect you want to reach.

The glow effect can be more than 12 hours. The brightness of the glow getting weaker as the time passing by.

The glow powder can be used in many applications, like glow ink for printing, glow coating for indoor/outdoor, glow plastic products, safety sign products for improving safety in emergency situations, and energy saving.

Add luminous powder to the transparent resin, add luminous powder according to the brightness effect you want to achieve, and the addition ratio should not exceed 50%.

The luminous powder added in the ink absorbs and stores the light energy during the day, and then releases the light in the dark.

Phosphorescent ink is the ink containing the luminous powder and transparent ink. The feature is that it can glow in the dark.

Mix glow powder with transparent ink. According to past experience, it is recommended that the adding ratio of luminous powder is 40%-50% by weight.

Glow in the dark paint from Glow Technology is non-toxic, no radiation, environmental protection and non- VOC.

The glow pigment is creamy white to yellowish color, so the paint is the same color as the pigment.

Normally can last 10-12 hours, but the brightness will be getting weaker as time goes by, the energy will be down. The first hour will be the brightest.

Yes, it is creamy white color during the day.

Almost all visible light energizes luminous powder. The UV light charge is the fastest,full in five minutes;At noon the sun can fill up for ten to fifteen minutes. Red light can not charge the glow powder.

The base color is preferred to be white, if it is dark, you can apply a layer of primer; If you want a better luminous effect, you can spray twice. The glow effect depends on the quality of the glow pigment added, usually yellow-green is the brightest color and red color is the weakest.

The brightness of glow in the dark paint depends on the quality and the adding ratio of the glow pigment. Use ultra-high brightness glow pigment and the adding ratio can be up to 40% to 50% by weight.

Glow Technology’s glow in the dark paint, ultra-high brightness glow effect and long afterglow time. It can be used interior and exterior with good abrasion resistance and long service life.

Yellow-Green glow powder is the brightest.

The glow can last for 12 hours or more. It is glass material, so the service life is more than 10 years.

Artificial luminous stone is a kind of man-made glow in the dark stone, also called artificial luminous crushed stone, which is a high-tech self-luminous product. The composition is alkaline earth aluminate and silicate activated by rare earth elements.

Applying a layer of transparent cover paint on the surface of the luminous paint can extend the service life of the luminous paint.

If you want the clothes to glow in the dark, you can mix the luminous powder and ink(for fabric) to print on the clothes; or mix the silk thread and the luminous powder to directly make a line that glows in the dark.

No more than 100 mesh, more delicate surface 250 mesh to 400 mesh.

In addition to being related to the quality of the luminous paint itself, there are also traffic flow, pedestrian flow and construction environment.

①It is related to the construction temperature, the quality of the white primer and the top transparent paint, etc.

②Construction according to our instruction, theoretically speaking, the pedestrian walkway is workable for 3 years

③You can try it out with samples first. The temperature and humidity of each area are different. You need to try it yourself.

Generally, two layers are coated, the surface temperature should be below 60℃, and the single layer dosage is 200g. You need to try it in a small area first.

Yes, use exterior glow paint specially developed for metal smooth surface by Glow Technology.

This situation may occur if the paste is water-based and a non-waterproof glow powder is used.

If it is because of the phenomenon caused by our single variable luminous powder, it is that there is a substance in the paste that reacts with the luminous powder. This reaction changes the PH value of the printing paste. In addition, the thickening method he uses is likely to be fumed silica. It reacts with luminous powder.

According to past experience, pH 8-8.5 should be no problem based on clients’ feedback. But the the customer also should do the small test by himself.

It is recommended to try: 400 mesh waterproof luminous powder, because the luminous powder and the rubber or silicone are mixed, if the particle size can not be too big, it will be brighter, and it will not affect the surface smoothness.

We suggest using glow in the dark stone.

Below is the common average particle sizes:

100 mesh – 100 to 110 microns

200 mesh – 50 to 60 microns

250 mesh – 30 to 40 microns

400 mesh – 20 to 30 microns

10microns

Other particle sizes can be customized.

Pink-red glow in the dark pigment, day color is also red,not transparent.

The glow pigment is preferred to be mixed with transparent paint to have a great glow effect.

Yes. We have various choices of luminous powder.

color-card of glow powder

For the luminous stones application, it depends on the area of the flagstone path and the luminous density you want to achieve. More details, you can click here.

Yes, one of the common use for glow in the dark pigment is to make glow plastic utility products.

Yes, the white base color is preferred to achieve the best glow effect.

Glow in the dark pigments can be used in both the water-based paint industry and the solvent-based paint industry. There is waterproof glow pigment for the water-based paint.

Glow in the dark stone is recommended. Glow powder is very fragile and can only be mixed with transparent medium to have the glow effect.

Powders smaller than 400 mesh cannot be physically screened.

100 mesh – 100 to 110 microns

200 mesh – 50 to 60 microns

250 mesh – 30 to 40 microns

400 mesh – 20 to 30 microns

Ultra-fine powder: average particle size 10 microns.

If you want a fine surface, you can add 400 meshes; if you want a brighter effect and starry effect, you can add 100-200 meshes. It may be a bit large, and the particles can be seen by the naked eye.

The glow in the dark powder is measured as kilo or ton.

Yes, there are specially developed types for applying on metal surfaces.

It is a yellowish-white color during the day time. After the glow in the dark paint is full of energy, it can only be seen glowing in a dark environment.

We recommend you taking Glow Technology’s glow in the dark paint directly. Or you can use luminous powder to mix with your paint. But the first premise is that it must be a transparent paint. You need to control the viscosity of the paint to avoid the luminous powder from settling.

Glow Technology’s coated waterproof luminous powder can be washed. It is our patent product. It can be used for printing ink, water-based paint and etc.

It can be reused for unlimited times. After the glow in the dark things are left in a dark environment for a long time, its energy will be run out. You can recharge it under light, and it will glow again.

Almost make anything that you want to make it glow. Some detailed applications, such as glow in the dark egress signs, glow in the dark screen printing ink, cell phone case, toys, clothes, pavement wall-trick, etc. For more details, click the blog.

Pigments are a fine and loose powder, which are used for coloring paint, ink, plastic, fabric, cosmetics, food, and other materials. Glow in the dark pigment is a special inorganic pigment which are widely used for making safety signage, arts, crafts, decorations, toys and etc.

No more than 100 mesh, more delicate surface 250 mesh to 400 mesh.

Yes, it needs to be charged by light, like sunlight, LED light, UV light.

As long as the luminous powder is full of energy in the sun, it can continue to glow for more than 12 hours in the dark without any power supply.

Glow Technology glow in the dark powder is non-toxic and harmless, safe, and environmentally friendly.

The encapsulated waterproof luminous powder can be used in a water-based medium, the ordinary luminous powder can not

The luminous duration of the glow in the paint depends on the brightness level of the glowing powder used in the luminous paint. The higher the brightness level, the longer the glowing time. Generally, the bright time of the high-grade luminescent paint will last more than 12 hours. The glow effect can be repeated unlimited times. The paint film duration depends on climate, friction, and many other factors.

The afterglow time of glow in the dark pigment of Glow Technology can reach more than 12 hours.

Put the same particle size luminous powder under the same light, and record the brightness data and the length of the afterglow time. Choose the most suitable luminous powder according to your needs.

The glow in the dark pigment powder is a photoluminescent material that absorbs and stores light during the day and releases it in a dark environment.

It is recommended to buy from a professional manufacturer, and it is not recommended that non-professional people make their own luminous pigments.

Almost make anything that you want to make it glow. You can mix it into a colorless, clear, transparent, or semi-transparent neutral medium such as resin, wax, paint, ink, plastics, rubber, fabric, etc. There are numerous industrial applications for safety, for household use,for fun, etc. Some detailed applications, such as glow in the dark egress signs, glow in the dark screen printing ink, cell phone case, toys, clothes, pavement wall-trick, etc. For more details, click the blog.

Yes. The glow in the dark stars glow because they contain glow powder. It needs to be charged through visible light during the day before it can glow in a dark environment.

If Glow Technology’s top-quality glow powder is used, it can glow more than 12 hours. The glow in the dark stars is fully charged and placed in a dark environment, which will release 99% of energy within an hour, and the remaining 1% can last for more than 10 hours.

According to the definition of the World Luminous Association PSPA, as long as the brightness of the glow in the dark powder exceeds 0.32mcd/m2, it can be defined as that it is glowing. This brightness is the lowest brightness that the human eye can recognize in a completely dark environment.

Depending on the use environment of the luminous paint, humidity, temperature, friction, etc. will affect the durability of the luminous paint.

There are different types of glow in the dark paint, for ground, for the wall, for metals, for outdoor or for other surfaces and environment. The price of luminous paint can be consulted by professional manufacturer Glow Technology. They are a world-leading high-tech manufacturer of glow in the dark powder with over 20 years’ experience.

Glow Technology‘s glow in the dark powder is the brightest and has a long afterglow time over 12 hours. To check the brightness of luminous powder, it should be the same particle size and be charged with the same light sources.

The glow in the dark powder can be used unlimited times.

After the luminous powder is full of energy during the day, you can’t see it glows in bright places. Only in a dark environment can it glow for more than 12 hours. It can be full of energy during the day again, and this process can be circulated indefinitely.

It can’t. If the temperature is too high, the luminous powder will be destroyed. The glow in the powder is recommended to be used under 500℃.

It has powerful light absorption, light storage, and luminescence. It is a light-excited and light-storing luminescent powdery crystals, after being irradiated by natural light, daylight light, ultraviolet light, etc. And then slowly releases it in a fluorescent manner after stopping light irradiation. So at night or in a dark place, we can still see the light, lasting for several hours to ten hours.

The original glow color of glow in the dark powder is yellow-green, it is the brightest and most sold color. There are also another dyed 10 colors available.

Glow in the dark stars glow because of the addition of glow in the dark pigment. A few factors may cause this problem: The quality of the glow in the dark powder is not good, the proportion of the powder added is not enough, the plastic should be transparent to have good glow effect.

And the glow powder need to absorb light energy first to glow, so charge them first with light and then check.