Many factors can affect the glow effect of glow in the dark paint. Many people often ask us to put the luminous powder directly into their lacquer, will their lacquer be able to glow the same as our glow in the dark paint and can start construction instantly? However, glow in the dark paint is not so simple to make; we studied the viscosity for a long time to reach that balance.

Also, people sometimes confused with reflective paint, luminous paint, and fluorescent paint. To determine whether it is a suitable product for you, we will introduce the differences between them one by one. This is a very professional question, and i it is a problem that we need to explain repeatedly many times, which wastes both parties’ time and reduces work efficiency. Therefore, today I will introduce the difference of three special effect paints–reflective paint, luminous paint, and fluorescent paint, as well as those questions that everyone is curious about glow in the dark paint, why it doesn’t glow brightly.

Introduction of glow in the dark paint:

Glow in the dark paint is the high luminous intensity, Glow Technology long-lasting glowing paint can continuously emit light for about 12 hours.

The limited monotone plane can be expanded into a dreamy multi-dimensional space with singular brilliance. The decoration effect is creative. And it can be recycled indefinitely, with long service life, non-toxic, harmless and free of radioactive elements. It is a new generation of environmentally friendly decorative coatings.

Luminous paint is composed of luminous powder and liquid resin, so glow in the dark paint is an application of luminous powder. The quality of luminous powder and the proportion of glow powder added determines the brightness of glow in the dark paint.

Then the next question, what kind of glow in the dark powder is suitable for glow paint?

First of all, it depends on what basis you are applying and what effect you want to achieve

Glow Technology luminous paint can choose luminous powder of any particle size and brightness. The larger the particle size, the higher the viscosity of the paint, the fluidity will be weak, and it will not be conducive to construction. So it also depends on whether your technology supports it.

Knowing these, we will recommend you the most suitable luminous paint.

Can the luminous powder be added to your paint directly?

The first premise is that it must be a transparent paint. You need to control the viscosity of the paint to avoid the luminous powder from settling. If the thickness is not enough, you can choose the powder with the smallest particle size. So if you only need a small amount of glow paint, we suggest trying to mix the powder with your clear paint. If the required amount is large, we recommended you taking Glow Technology luminous paint directly.

The main applications of glow in the dark paint

Luminous paint can be used to display objects in a dark environment.

- Architectural decoration, interior decoration, painting, wall surface.

- Night object identification label, power switch, tool, or toolbox.

- Entertainment locations such as PUB, KTV, storefronts, large parties.

- Traffic signs, fire emergency escape system, military equipment, garden decoration.

- Clocks, buttons, instruments or indicators, radios, cameras.

- Bicycles, locomotives, automobiles, body patterns and aluminum rings, steel rings.

- Fishing equipment, aquarium equipment, flags, stickers, toys.

- General ornaments, stunning image painting, ceiling decoration, etc.

Precautions for luminous paint construction

To have the full performance of glow in the dark paint, complete and correct construction must be achieved. The following are the precautions in construction:

(1)Do a complete surface treatment: the appropriateness of the surface treatment has a significant influence on the performance and life of the paint film, so it is necessary to determine whether the surface is smooth and absorbs water. Completely remove rust, oil, and other foreign materials and wait for thoroughly dry before applying to brush.

(2)After the substrate is processed, the primer can be applied. After the luminous paint is completely dry, the topcoat can be used (expend the glow in the dark paint service life)

(3)Painting process: the glow in the dark paint can be sprayed, brushed, or rolled. The thickness of the one layer should not be too thick. Otherwise, it is easy to produce bubbles, wrinkling, and other phenomena. Therefore, it is necessary to have appropriate control and do multi-layer coating construction.

(4)In the case of multi-layer coating, wait for the lower layer paint to dry before applying another layer. If it is not dry, then it will be easy to wrinkle or even peel off the underlying paint. Therefore, the upper coat of paint should not be applied until the lower layer of paint is completely dry.

(5)Avoid construction in low temperatures and humid climate. When the temperature drops below 5 ℃, it will enormously reduce the dryness of the paint, and when the humidity is above 85RH%, it will affect the adhesion.

(6)Remove dust as much as possible: Dust will not only affect the performance of the paint film but also damage the appearance, so clean it as much as possible.

(7)Quick-drying: It can be heated and dried at 65 ℃ ± 5 ℃, and the drying time is about 6-10 minutes.

Next, let's introduce the nature and differences between three special effect paints, reflective paint, and fluorescent paint.

Luminous paint characteristics:

it absorbs light during the day and glows at night when there is no light, or the light source is very weak. The darker the environment, the brighter the effect. Generally applicable to safety signs, escape signs, etc. It can be used as an artistic lacquer, objects, or places carefully painted will be gorgeous and beautiful when they glow at night. It is commonly used in automobile modification, handicrafts, safety instruction signs, etc.

It has high luminous intensity and long afterglow time. It can be used with a special primer and curing agent for glow in the dark paint. It can be sprayed, rolled, or brushed on different substrates: stainless steel, aluminum alloy, iron plate, wood, cement, etc.

Fluorescent paint characteristics:

It is often confused by people with luminous paint and reflective paint. In particular, the most significant feature of fluorescent paint is that it does not glow or reflect without light sources. Only under the illumination of the light source, it will be gorgeous and very colorful.

They are commonly used in hotel lobby decoration, KTV entertainment venues, product decoration, architectural decoration, etc.

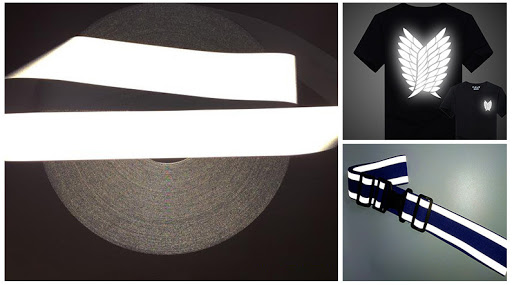

Reflective paint characteristics:

At night or in a poor light situation, when a spotlight shines on the paint surface, the unique reflective material contained in the reflective paint will reflect more than 90% of the light source back to form a reflective effect. (Such as car lights)

Reflective paint is generally suitable for the marking of underground parking lots, roadside anti-collision piers, barriers, etc.